Description

Table of Content – Groundsmaster 360 (with Kubota Engine)

- Title Page

- Revision History

- Reader Comments

- Preface

- Table Of Contents

- 1 – Safety

- General Safety Instructions

- Before Operating

- While Operating

- Maintenance and Service

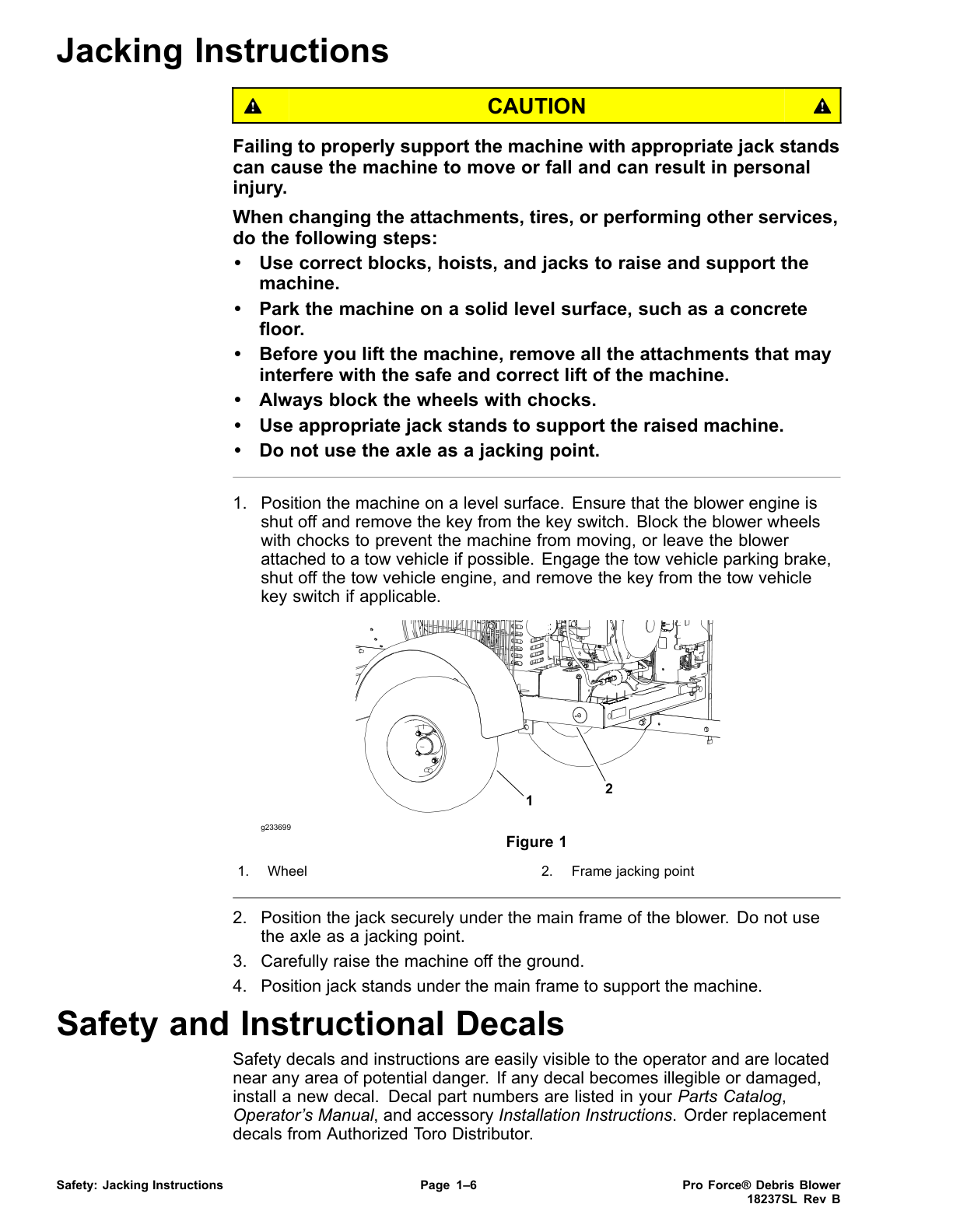

- Jacking Instructions

- Safety and Instruction Decals

- 2 – Product Records and Maintenance

- Product Records

- Maintenance

- Equivalents and Conversions

- Decimal and Millimeter Equivalents

- U.S. to Metric Conversions

- Torque Specifications

- Fastener Identification

- Using a Torque Wrench with an Offset Wrench

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

- Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

- Other Torque Specifications

- Conversion Factors

- 3 – Kubota Diesel Engine

- Specifications

- Machines with 4 Cylinder Engine

- Machines with 3 Cylinder Engine

- General Information

- Operator’s Manual

- Adjustments

- Adjust Throttle Control

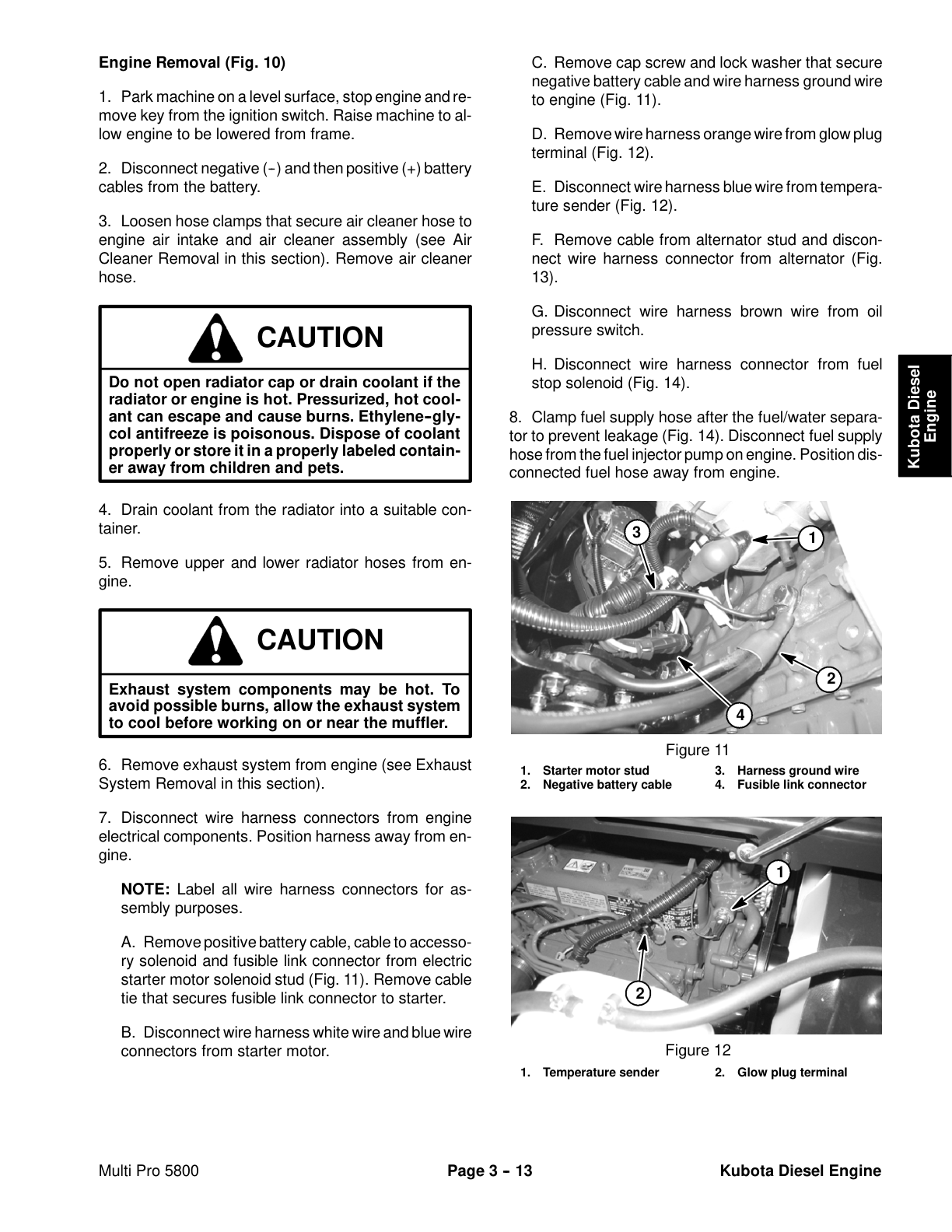

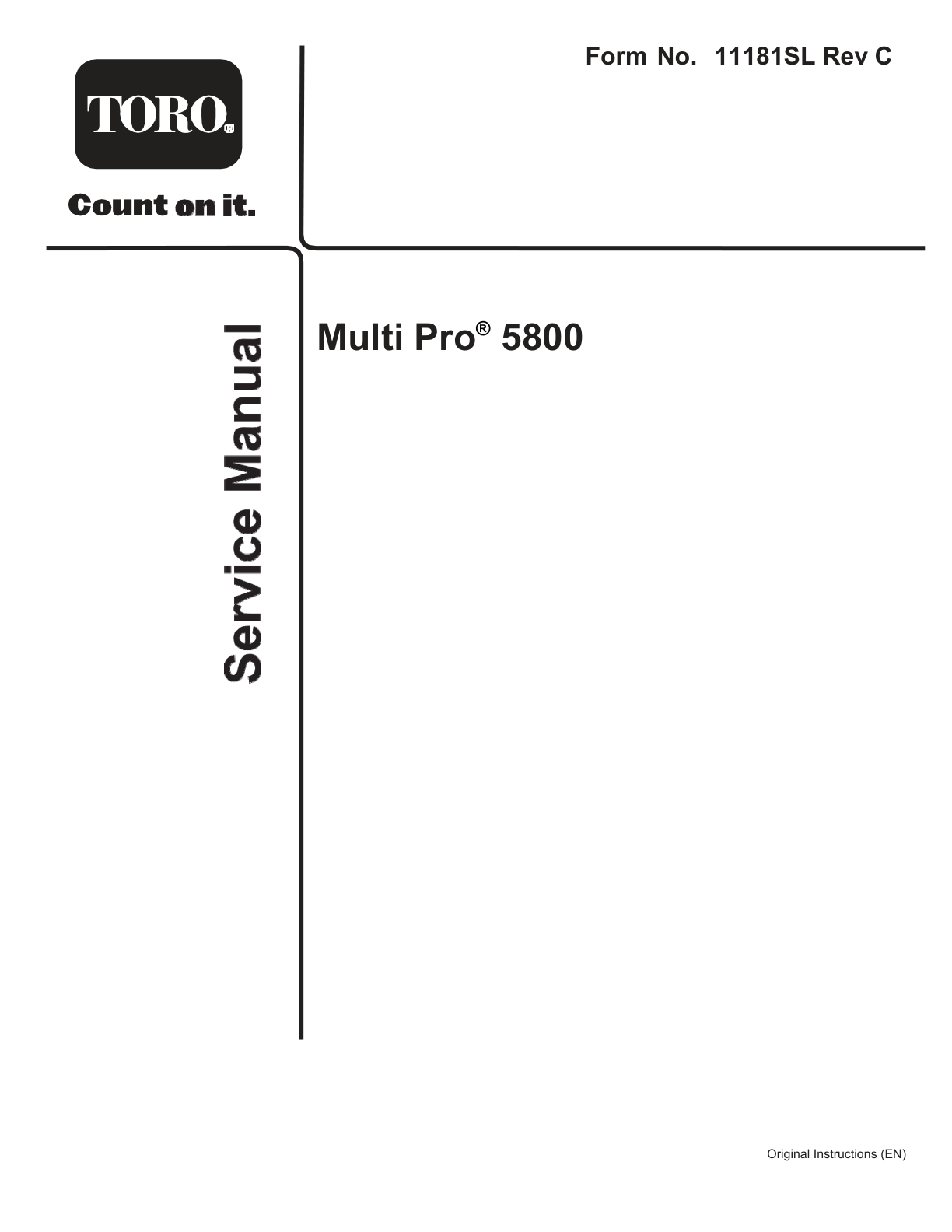

- Service and Repairs

- Air Cleaner Assembly

- Exhaust System

- Fuel System

- Radiator

- Engine

- KUBOTA WORKSHOP MANUAL, DIESEL ENGINE, 05−E3B SERIES

- KUBOTA WORKSHOP MANUAL, DIESEL ENGINE, 05−E4B SERIES

- 4 – Hydraulic System

- Specifications

- General Information

- Operator’s Manual

- Pushing Traction Unit

- Relieving Hydraulic System Pressure

- Traction Circuit Component Failure

- Hydraulic Hoses

- Hydraulic Hose and Tube Installation (O-Ring Face Seal Fitting)

- Hydraulic Fitting Installation (SAE Straight Thread O-Ring Fitting into Component Port)

- Hydraulic Schematics

- Hydraulic Flow Diagrams

- Traction Circuits: 2WD Machines

- Traction Circuits: 4WD Machines

- Steering Circuits: 2WD Machines

- Steering Circuit: 4WD Machines

- Lift Circuit: Raise

- Lift Circuit: Lower

- PTO Circuit

- Special Tools

- Hydraulic Pressure Test Kit

- 15 GPM Hydraulic Tester Kit (Pressure and Flow)

- 40 GPM Hydraulic Tester (Pressure and Flow)

- Hydraulic Hose Kit

- O-ring Kit

- High Flow Hydraulic Filter Kit

- Hydraulic Test Fitting Kit

- Wheel Hub Puller

- Troubleshooting

- General Hydraulic System Problems

- Traction Circuit Problems

- PTO Circuit Problems

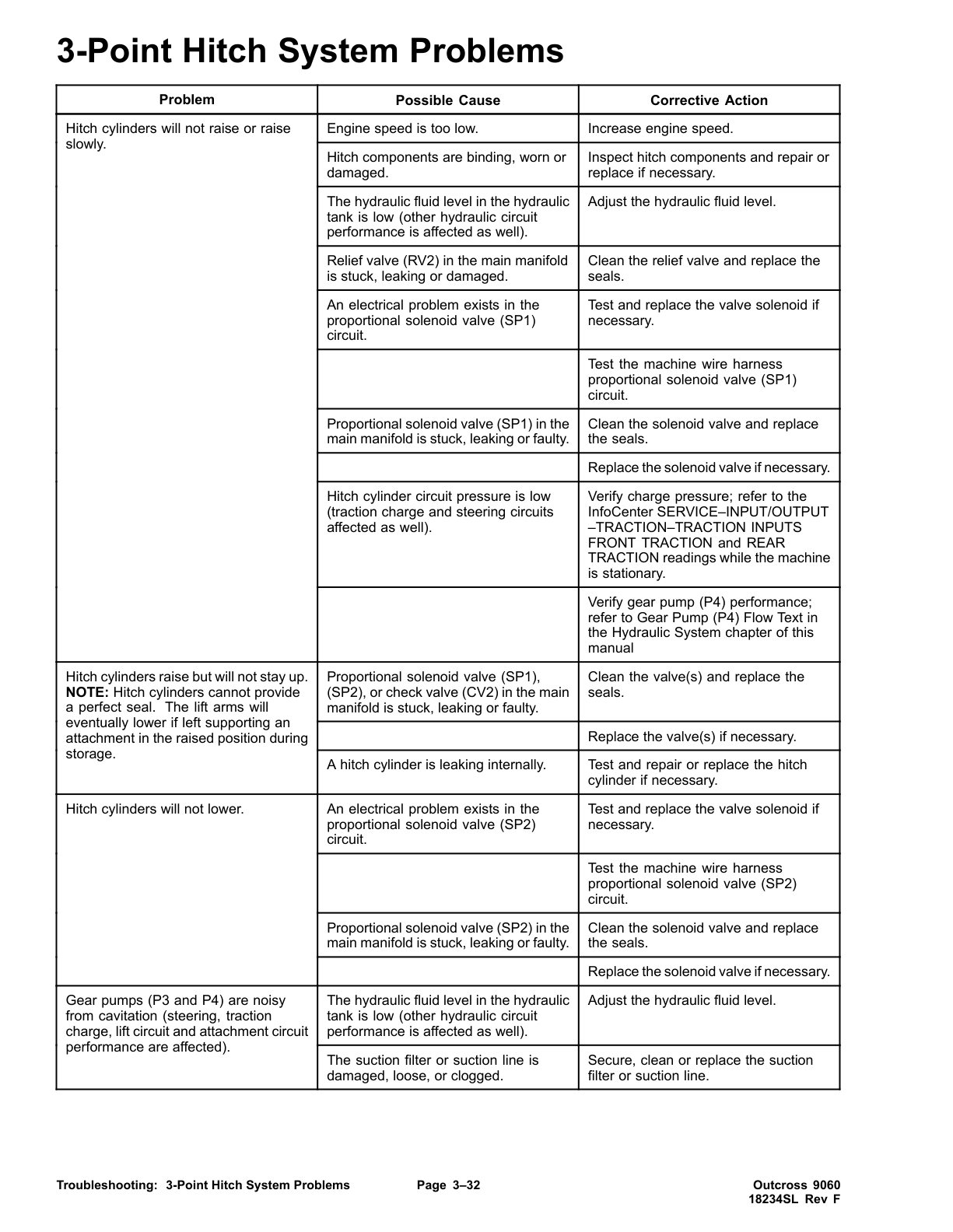

- Steering and Lift, Lower Circuit Problems

- Testing

- Traction System Operation Testing

- Charge Relief Valve Pressure Test (Using Pressure Gauge)

- Traction Relief Valve Pressure Test (Using Pressure Gauge)

- Transmission Piston Pump Flow Test (Using Tester with Pressure Gauges and Flow Meter)

- Rear Wheel Motor Efficiency Test (Using Tester with Pressure Gauges and Flow Meter)

- PTO Pressure Valve Test (Using Pressure Gauge)

- Implement Relief Pressure Test (Using Pressure Gauge)

- Gear Pump Flow Test (Using Tester with Pressure Gauges and Flow Meter)

- Lift Cylinder Internal Leakage Test

- Service and Repairs

- General Precautions for Removing and Installing Hydraulic System Components

- Check Hydraulic Lines and Hoses

- Flush Hydraulic System

- Filtering Closed-Loop Traction Circuit

- Charge Hydraulic System

- Hydraulic Tank

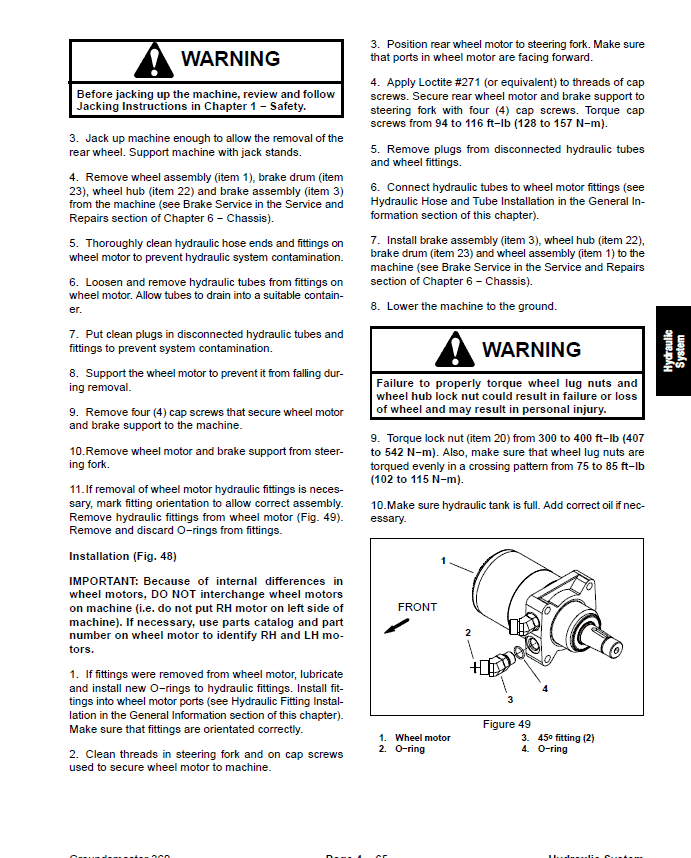

- Rear Wheel Motors

- Front Wheel Motors (4WD Machines)

- Wheel Motor Service

- Traction Linkage Assembly (Serial Number Below 313999999)

- Traction Linkage Assembly (Serial Number Above 314000000)

- Transmission

- Transmission Service

- CrossTraxTM AWD Control Manifold (4WD Machines)

- CrossTraxTM AWD Control Manifold Service (4WD Machines)

- Control Manifold Cartridge Valve Service

- Gear Pump

- Gear Pump Service

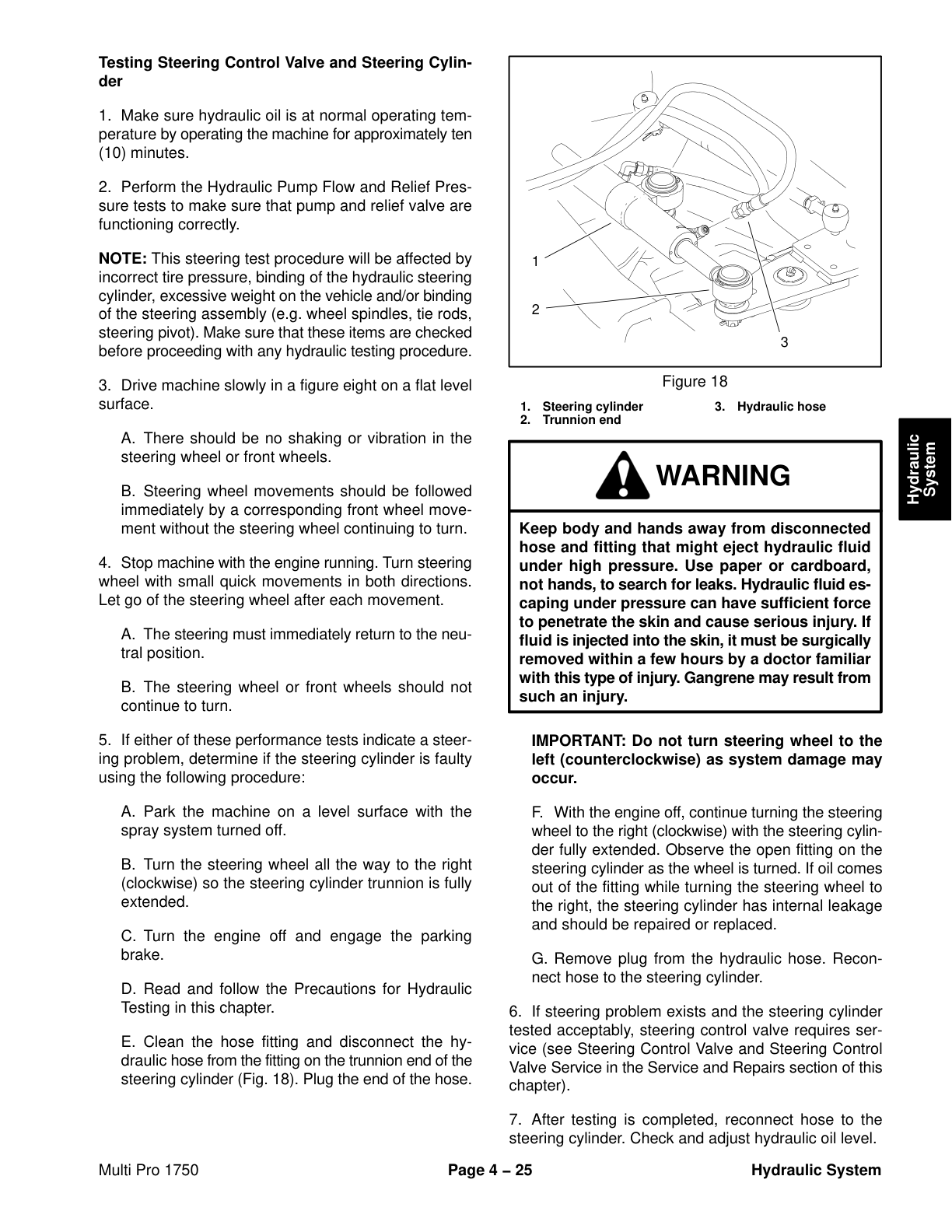

- Steering Control Valve

- Steering Control Valve Service

- Steering Cylinder (Serial Number Below 314999999)

- Steering Cylinder (Serial Number Above 315000000)

- Steering Cylinder Service

- Steering Control Manifold (4WD Machines)

- Steering Control Manifold Service (4WD Machines)

- Deck Lift Manifold

- Deck Lift Manifold Service

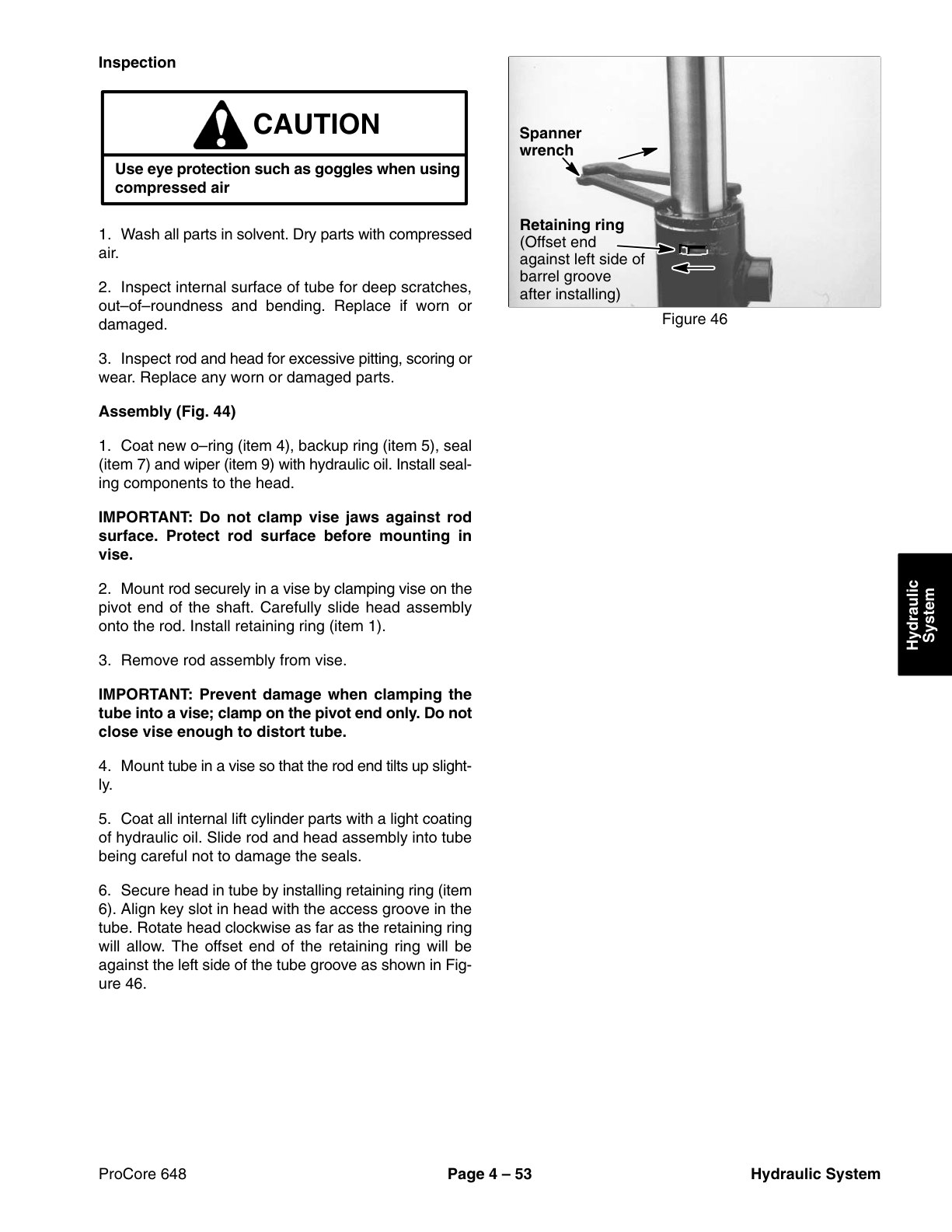

- Lift Cylinder

- Lift Cylinder Service

- Quick Attach System (QAS) Control Manifolds (Optional Kit for 4WD Machines)

- Quick Attach System (QAS) Control Manifold Service (Optional Kit for 4WD Machines)

- Oil Cooler

- PARKER TORQMOTORTM SERVICE PROCEDURE(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

- 5 – Electrical System

- General Information

- Operator’s Manual

- Electrical Drawings

- Toro Electronic Controller (TEC) (4WD Machines)

- CAN-bus Communications (4WD Machines)

- Standard Control Module (SCM) (2WD Machines)

- Special Tools

- Multimeter

- Diagnostic Display (4WD Machines)

- Battery Terminal Protector

- Dielectric Gel

- Battery Hydrometer

- Troubleshooting

- Diagnostic Light (4WD Machines)

- Diagnostic Display (4WD Machines)

- Standard Control Module Logic Chart (2WD Machines)

- TEC Logic Chart (Machines with 4WD)

- Starting Problems

- General Run and Transport Problems

- Cutting Deck Operating Problems

- 4 Wheel Steer Operating Problems (4WD Machines)

- Electrical System Quick Checks

- Battery Test (Open Circuit Test)

- Charging System Test

- Glow Plug System Test

- Check Operation of Interlock Switches

- Adjustments

- Traction Neutral Sensor

- Parking Brake Sensor

- Steering Home Sensor (4WD Machines)

- Component Testing

- Ignition Switch (Serial Number Below 312000300)

- Ignition Switch (Serial Number Above 312000300)

- Indicator Lights

- Hour Meter

- Fuses (2WD Machines)

- Fuses (4WD Machines)

- Operator Cab Fuses (4WD Machines with Operator Cab)

- PTO Switch

- Deck Lift Switch

- Steering Selector Switch (4WD Machines)

- Air Conditioning Switch (4WD Machines with Operator Cab)

- Windshield Washer, Wiper Switch (4WD Machines with Operator Cab)

- Seat Switch

- Traction Neutral Sensor

- Parking Brake Sensor

- Steering Home Sensor (4WD Machines)

- Standard Control Module (2WD Machines)

- Toro Electronic Controller (TEC) (4WD Machines)

- Fusible Links

- PTO Solenoid Valve Coil

- Hydraulic Solenoid Valve Coils

- Main Power, Glowith Start (4WD Machines) and Cab Power (4WD Machines with Operator Cab) Relays

- Deck Lift Relay (2WD Machines)

- High Temperature Warning Switch (Machines without Operator Cab)

- High Temperature Shutdown Switch (Machines without Operator Cab)

- Dual Temperature Switch (Machines with Operator Cab)

- Oil Pressure Switch

- Fuel Pump

- Fuel Stop Solenoid

- Glow Controller (2WD Machines)

- Service and Repairs

- PTO Solenoid Valve Coil

- Hydraulic Manifold Solenoid Valve Coils

- Battery Storage

- Battery Care

- Battery Service

- 6 – Chassis

- Specifications

- General Information

- Operator’s Manual

- Special Tools

- Wheel Hub Puller

- Steering Alignment Tools

- Adjustments

- Brake Adjustment

- Steering Stop Adjustment

- Wheel Alignment

- Service and Repairs

- Wheels

- Brake Service

- Brake Cables

- Front Spindle Assembly (2WD Machines)

- Rear Steering Fork

- Front Steering Fork

- Front Steering Assembly

- Rear Steering Assembly

- Steering Assembly Bushing Service

- Frame Assembly

- Steering Column

- PTO Drive Shaft

- PTO Drive Shaft Cross and Bearing Service

- Cutting Deck Lift Assembly

- Control Console

- Storage Compartment (Machines without Operator Cab)

- Operator Seat

- Operator Seat Service (Machines without Operator Cab)

- Operator Seat Service (Machines with Operator Cab)

- Hood

- 7 – Cutting Deck

- General Information

- Cutting Deck Specifications

- Operator’s Manual

- Factors That Can Affect Cutting Performance

- Service and Repairs

- Blade Stopping Time

- Cutting Deck Removal and Installation

- Idler Assembly

- Blade Spindle

- Blade Spindle Service

- Gearbox

- Cutting Deck Pull Links

- 8 – Operator Cab (Serial Number Below 315000000)

- General Information

- Operator’s Manual

- Electrical Components and Schematic

- Air Conditioning System

- Cab Heater System

- Service and Repairs

- General Precautions for Removing and Installing Air Conditioning System Components

- Air Conditioning Compressor

- Roof Assembly

- Air Conditioning Condenser Assembly

- Heater, Evaporator Assembly

- Windshield Wiper

- Storage Compartment

- 8.1 – Operator Cab (Serial Number Above 315000000)

- General Information

- Operator’s Manual

- Electrical Components, Schematics and Wire Harness Drawings

- Air Conditioning System

- Cab Heater System

- Air Conditioning System Performance

- Service and Repairs

- General Precautions for Removing and Installing Air Conditioning System Components

- Air Conditioning Compressor

- Roof Assembly

- Heating and Air Conditioning Components

- A, C Condenser Fan Assembly

- A, C Condenser Assembly

- Mixing Box Assembly

- Heater and A, C Evaporator Cores

- Blower Fan

- Windshield Wiper Assembly

- VALEO COMPRESSOR SERVICE MANUAL

- 9 – Foldout Drawings

- Electrical Drawing Designations

- Wire Color

- Wire Size

- Hydraulic Schematics

- Groundsmaster 360 with 2WD (Serial Number Below 313999999)

- Groundsmaster 360 with 2WD (Serial Number Above 314000000) Shown with Optional Kits Installed

- Groundsmaster 360 with 4WD (Serial Number Below 313999999

- Groundsmaster 360 with 4WD (Serial Number Below 313999999) Shown with Optional Kits Installed

- Groundsmaster 360 with 4WD (Serial Number Above 314000000) Shown with Optional Kits Installed

- Electrical Schematics

- Groundsmaster 360 with 2WD (Serial Number Below 312000300)

- Groundsmaster 360 with 2WD (Serial Number Above 312000300)

- Groundsmaster 360 with 4WD (Serial Number Below 312000300)

- Groundsmaster 360 with 4WD (Serial Number Above 312000300)

- Groundsmaster 360 Operator Cab (Serial Number Below 314999999)

- Groundsmaster 360 Operator Cab (Serial Number Above 315000000)

- Groundsmaster 360 Electrical Accessories Kit (Optional)

- Wire Harnesses

- Groundsmaster 360 with 2WD (Serial Number Below 312000300)

- Groundsmaster 360 with 2WD (Serial Number Above 312000300)

- Groundsmaster 360 with 4WD (Serial Number Below 312000300)

- Groundsmaster 360 with 4WD (Serial Number From 312000301 to 313999999)

- Groundsmaster 360 with 4WD (Serial Number Above 314000000)

- Operator Cab (Serial Number Below 314999999)

- Operator Cab (Serial Number Above 315000000)

- Operator Cab Interconnect (Serial Number Below 314999999)

- Operator Cab Interconnect (Serial Number Above 315000000)

- Groundsmaster 360 Electrical Accessories Kit (Optional)

Rate this product

You may also like